Thus far my work could be seen a bandaid to the larger symptom of clothing not being created to under go such friction. To address unique wear patterns from the outset, integrating reinforced areas into the initial manufacturing process is needed. This proactive approach would then eliminate the need for after-the-fact patchwork, ensuring garments are both functional and aesthetically pleasing from the start.

I started by testing out traditional methods for reinforcement like what you may see in the heel of a sock or a double sided garment.

While these methods worked well (image 1-4), I ran into the same initial issue; These were still organic materials and would therefore eventually degrade too.

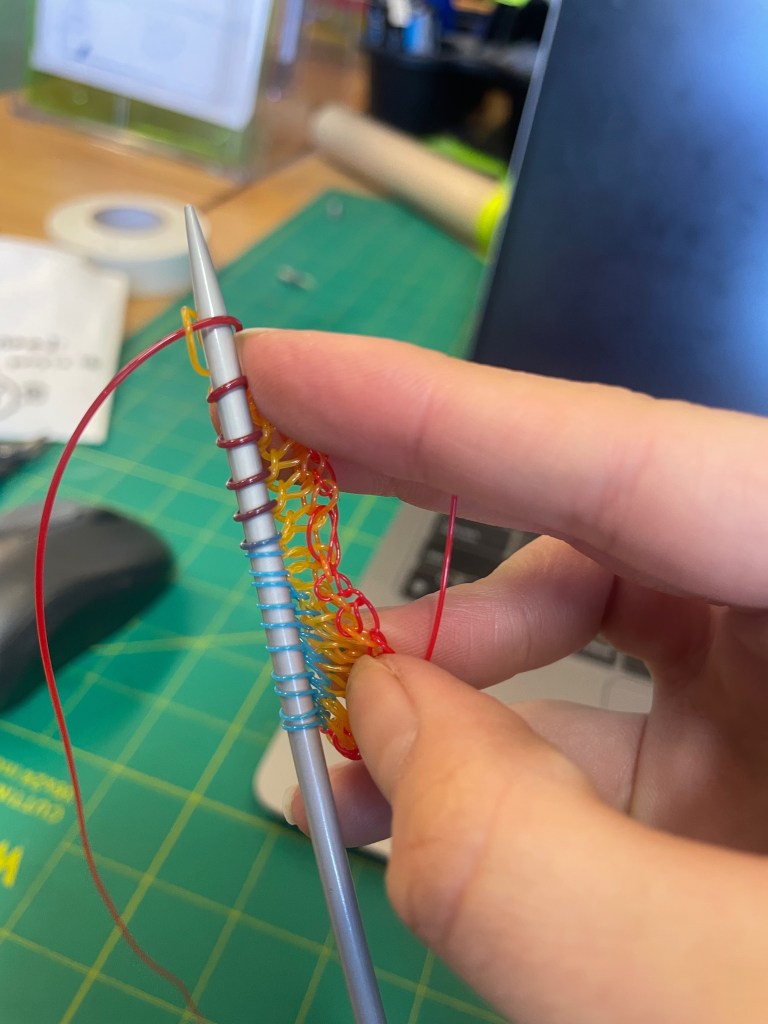

At the same time I was still 3D printing my 48 squares and noticed I produced some waste material everytime I purged out the machine. Because I had been knitting so much, this waste started to look a lot like yarn…

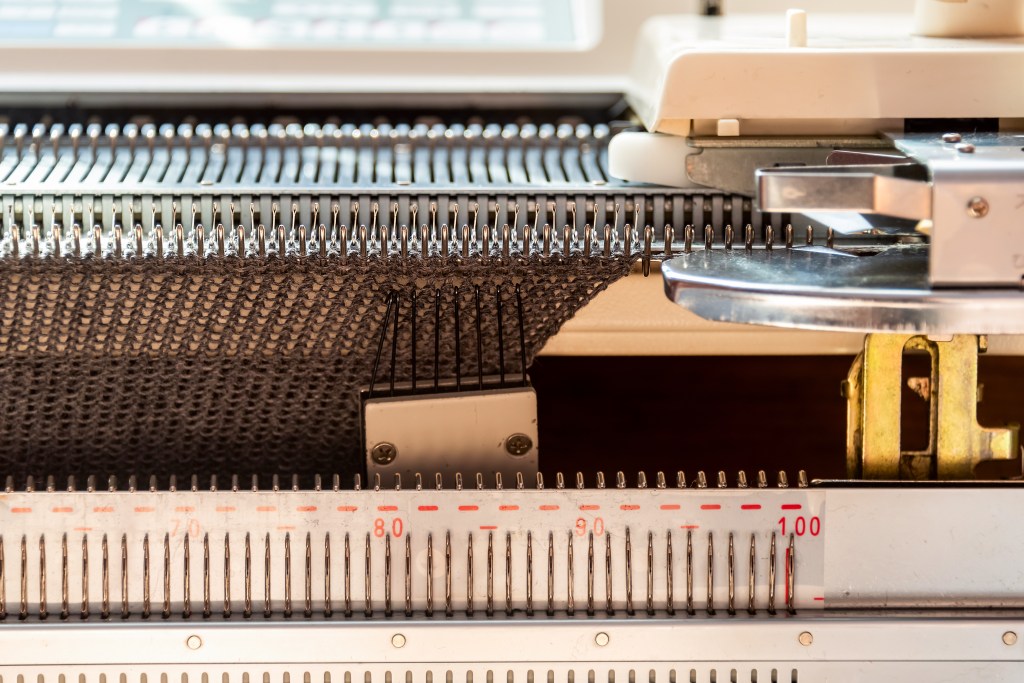

The image to the left was my very first test to see if I could translate from manual knitting to a knitting machine which would become my proof-of-concept for manufacturing.

I then set off to make sweaters for me, Emma, and Sarah, each sweater being reinforced with this TPU thread in high wear areas.

I had never seriously used a knitting machine before and so had a large learning curve. I relied heavily on Youtube as well as Professor Sonia Roberts who granted me acess to her knitting machines in Wesleyan’s robotics lab. Throughout this long process I was constantly learning better methods of inserting the TPU into each sweater. (Sorry to Sarah whose sweater was first :,) .)

Video shows eight rows, 800% sped up