Research on and Application of 3D Printed Textiles

[Continuation of How Do You Wear? senior thesis]

Now that I had consistent support from Everlane — and knew I’d be able to produce more sweaters than originally planned — I ran into two new challenges. With three users (myself, Emma, and Sarah) and multiple wear patterns to design for, I needed to rethink my methods:

- Durability: My initial patch method — hand embroidery on cotton fabric — was soft and meaningful, but not built to withstand long-term wear. I needed something more resilient, but still flexible and textile-like. It had to move with the sweater and be sewable without compromising comfort.

- Scalability: While embroidery was personal and expressive, it was also labor-intensive. If I wanted to expand the project — or think toward systems-level implementation — I had to develop a faster, repeatable process that still allowed for individualization.

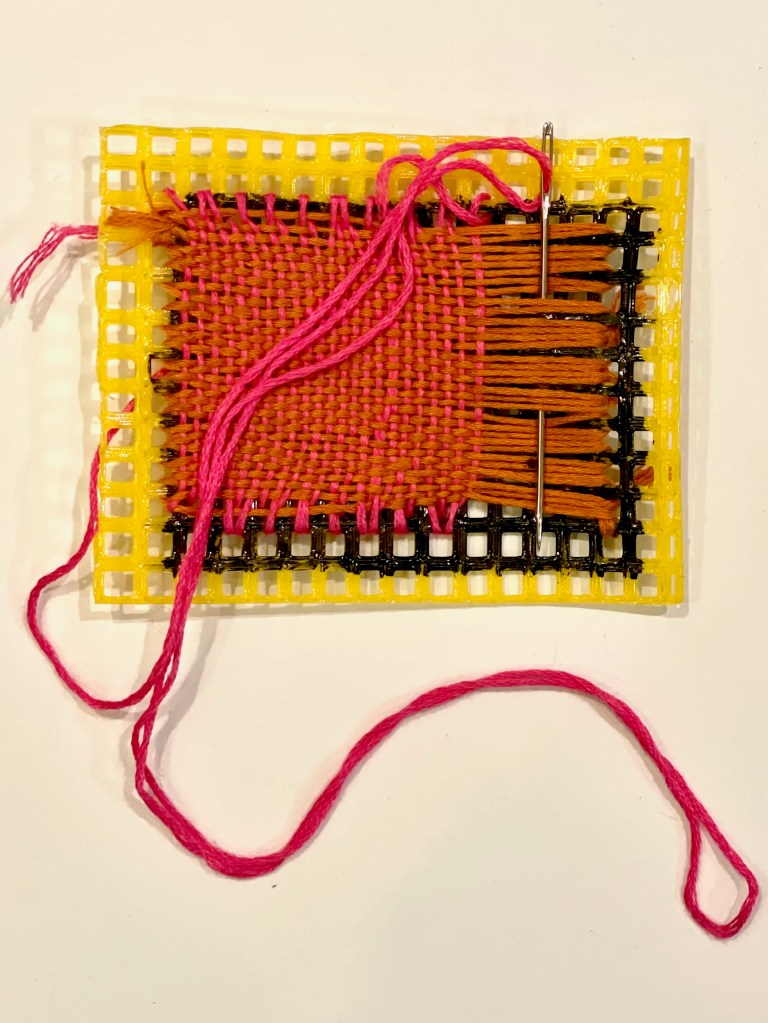

These questions led me to experiment with 3D printed textiles — specifically, using TPU filament to create patches that could reinforce sweaters while holding narrative and design intention. I had already done some initial research on 3D printed textiles from a project junior fall in which I created a 3D printed arm band tool so had a jumping off point.

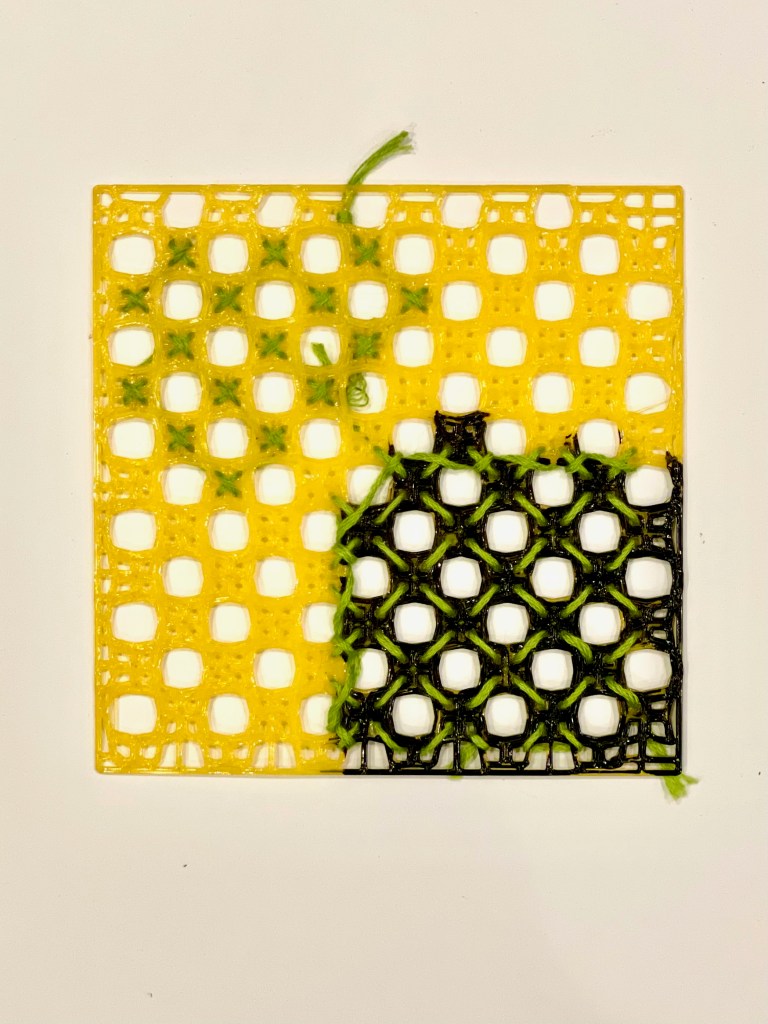

These first trials were super informative on both my possibilities and limitations. I knew that I could figure out how to get a thinner, more flexible pattern, however moving from Rhino to Cura created some issues. The 3D models that I brought into Cura were not being read by the slicer in the intended way and resulted in much thicker and therefore less flexible prints that would be uncomfortable to sew into sweaters.

In further trials I started to understand how to translate between these softwares better, figuring out how 3D models are read into the slicer and how the slicer then converts the file to gcode for the printer to read.

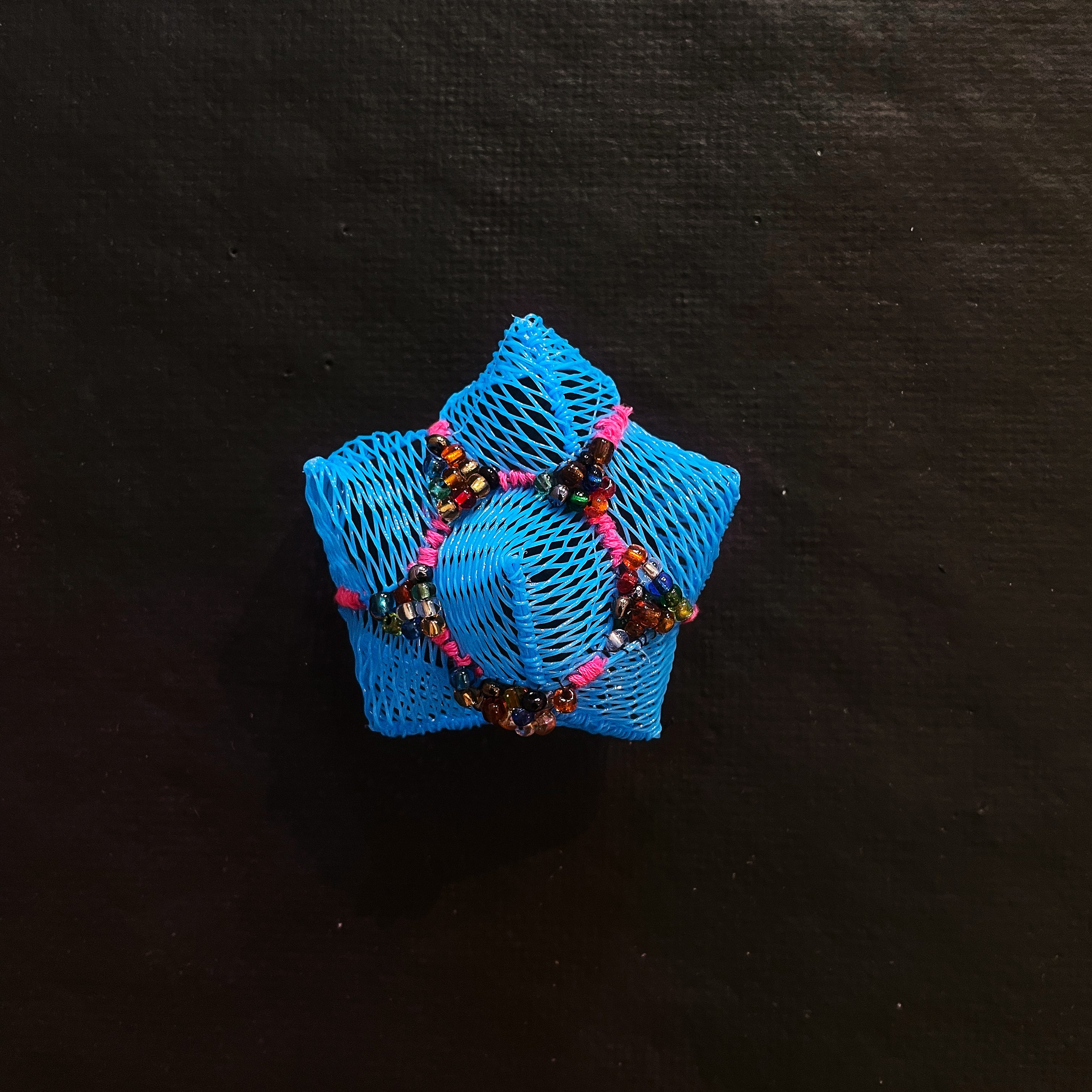

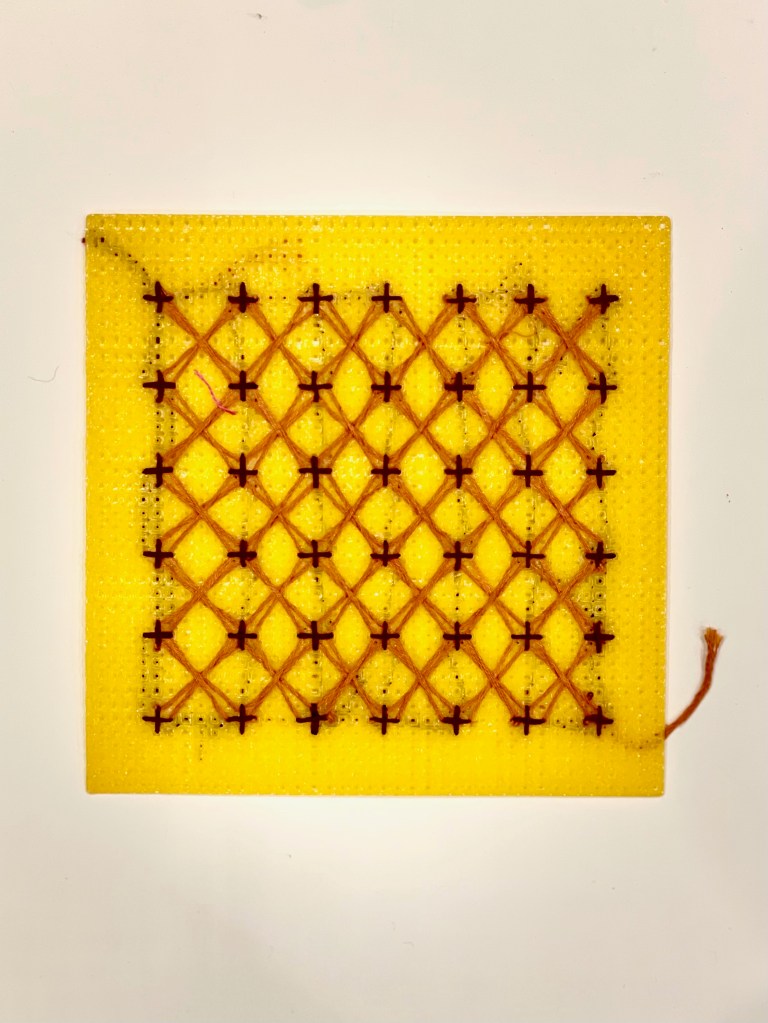

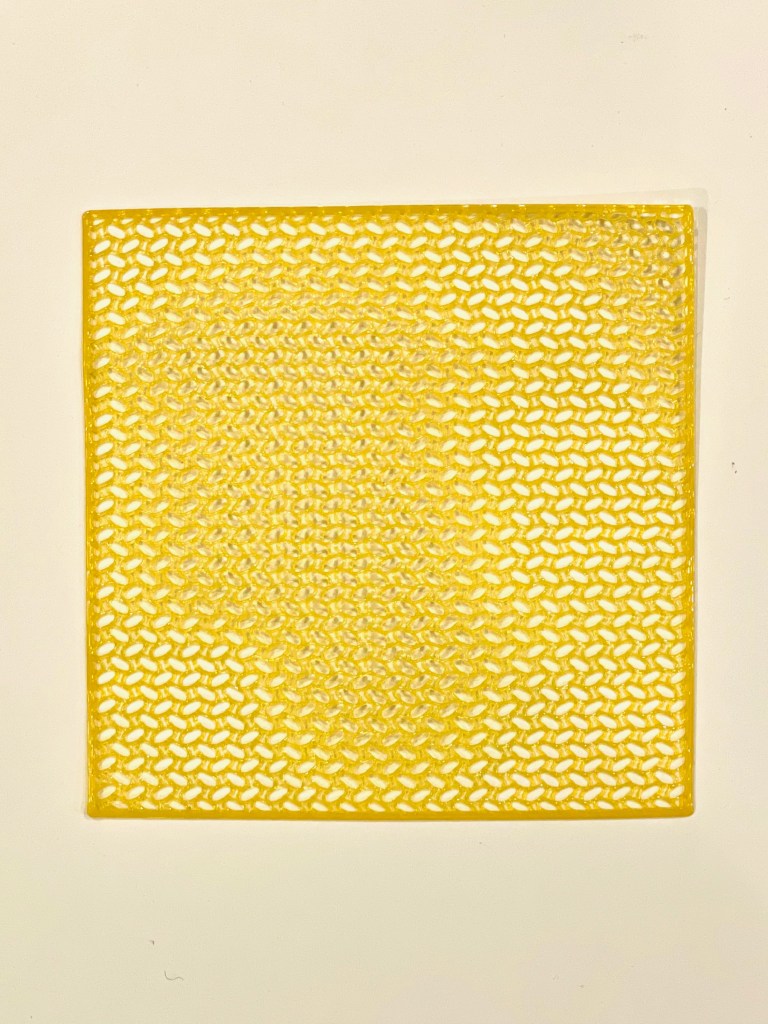

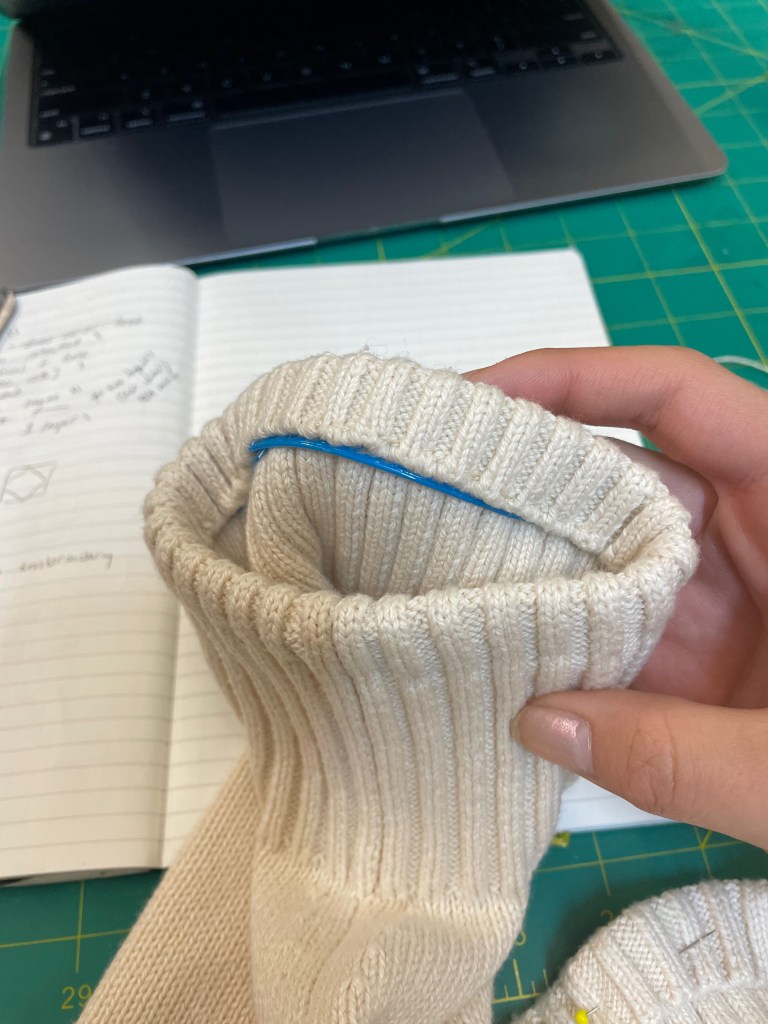

These next round of TPU textiles worked out much better. They were extremely durable yet still light, stretchy, and smooth. I could strategically add embroidery for aesthetic purposes but also to give some padding against the skin and the TPU textile still kept its material properties.

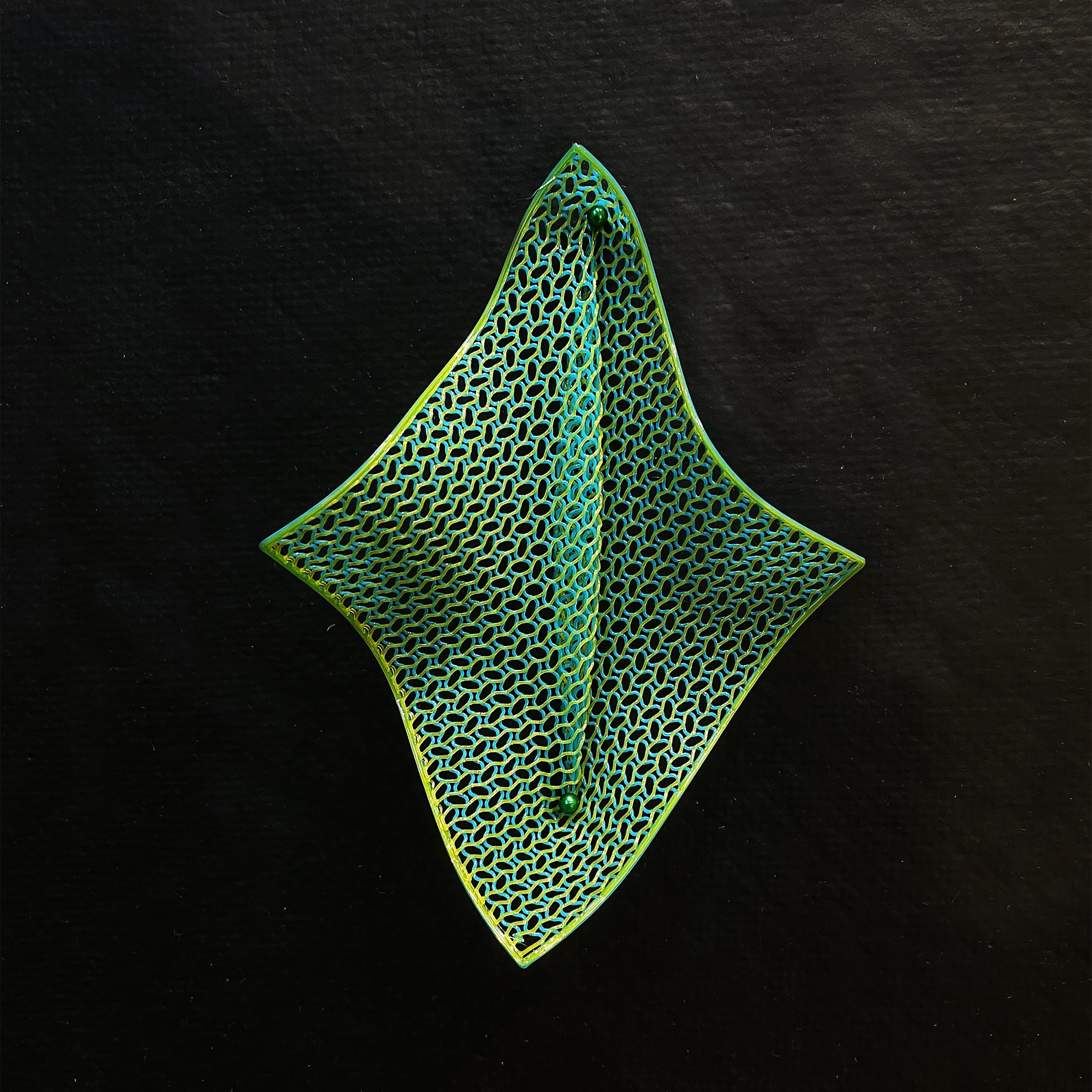

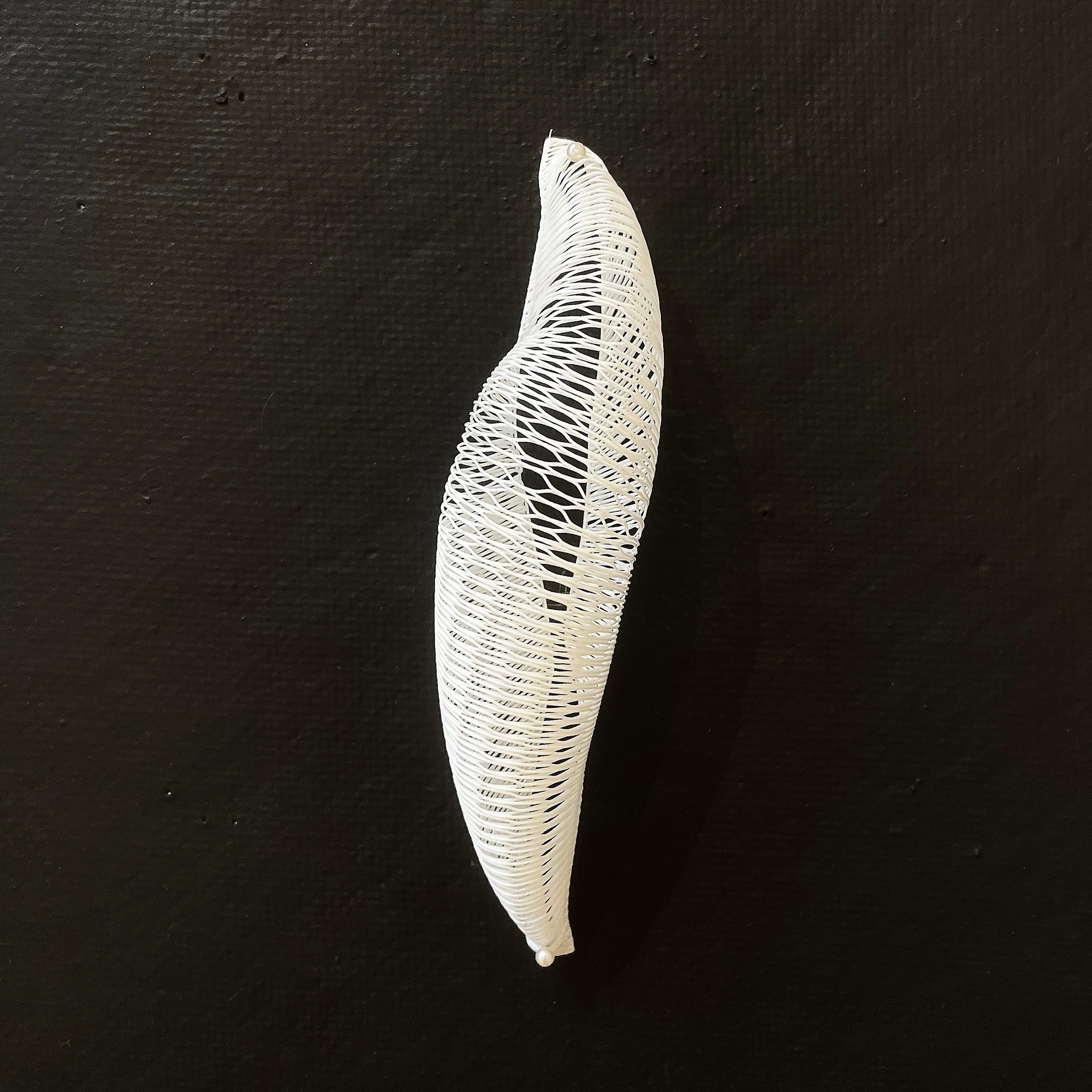

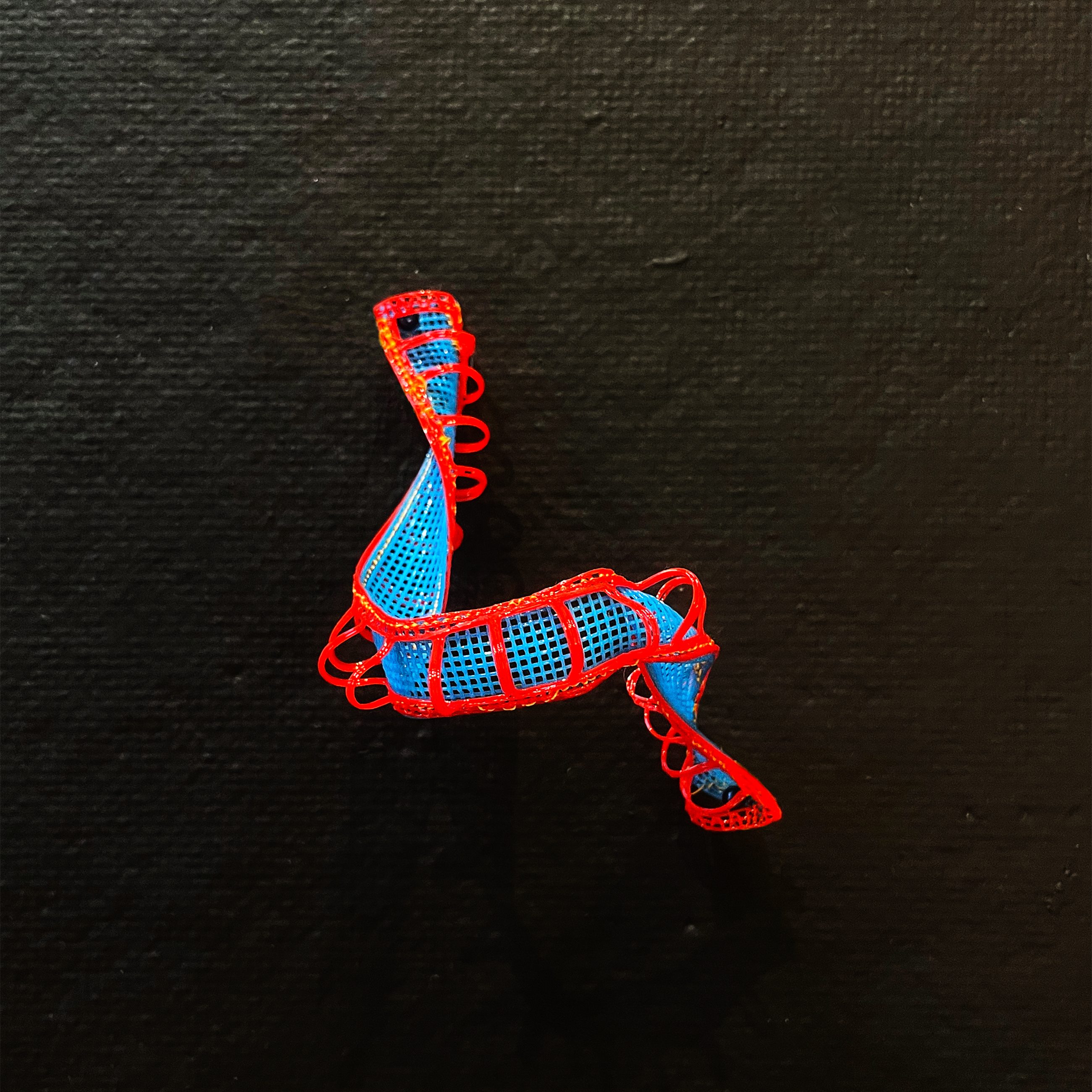

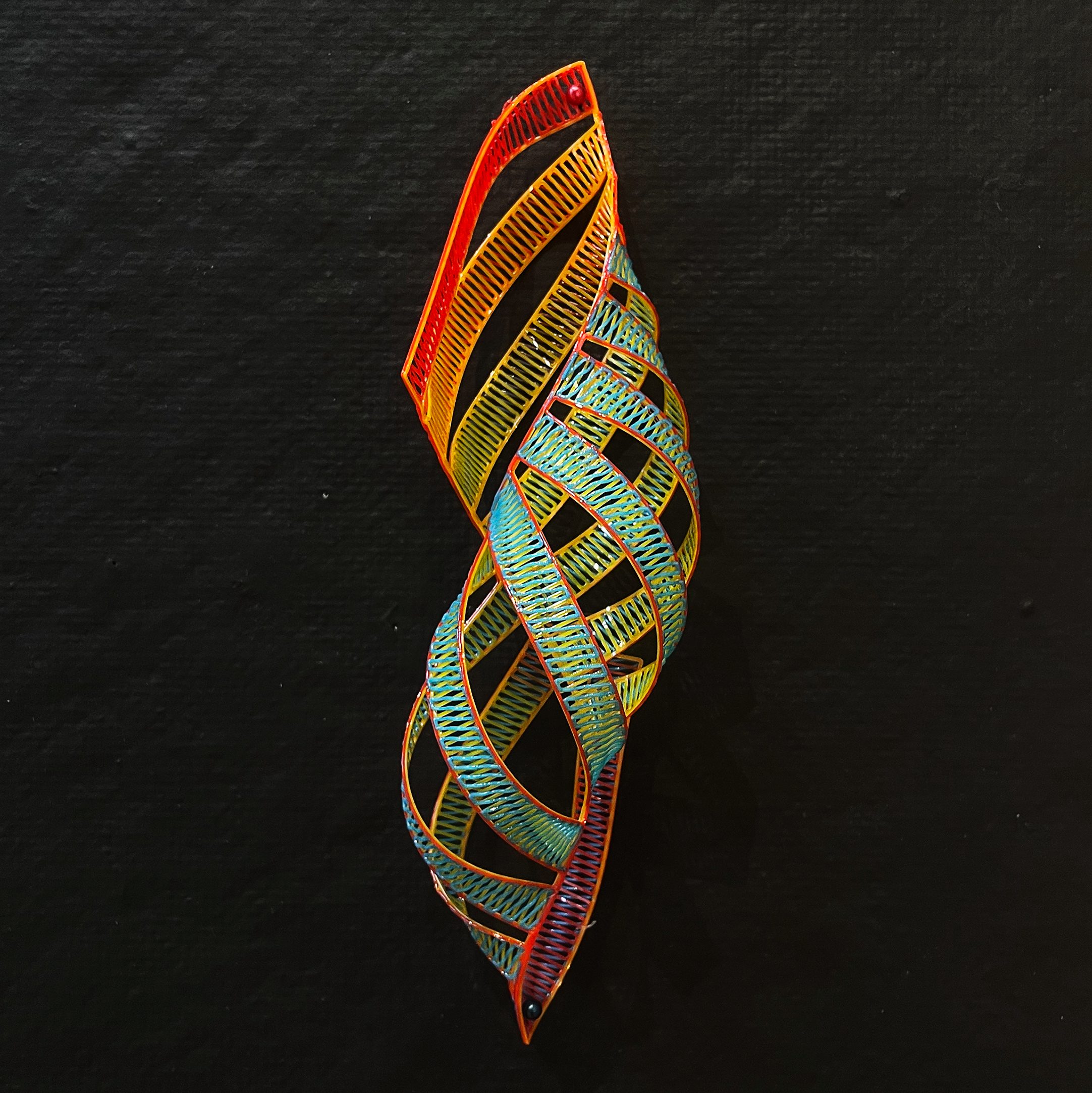

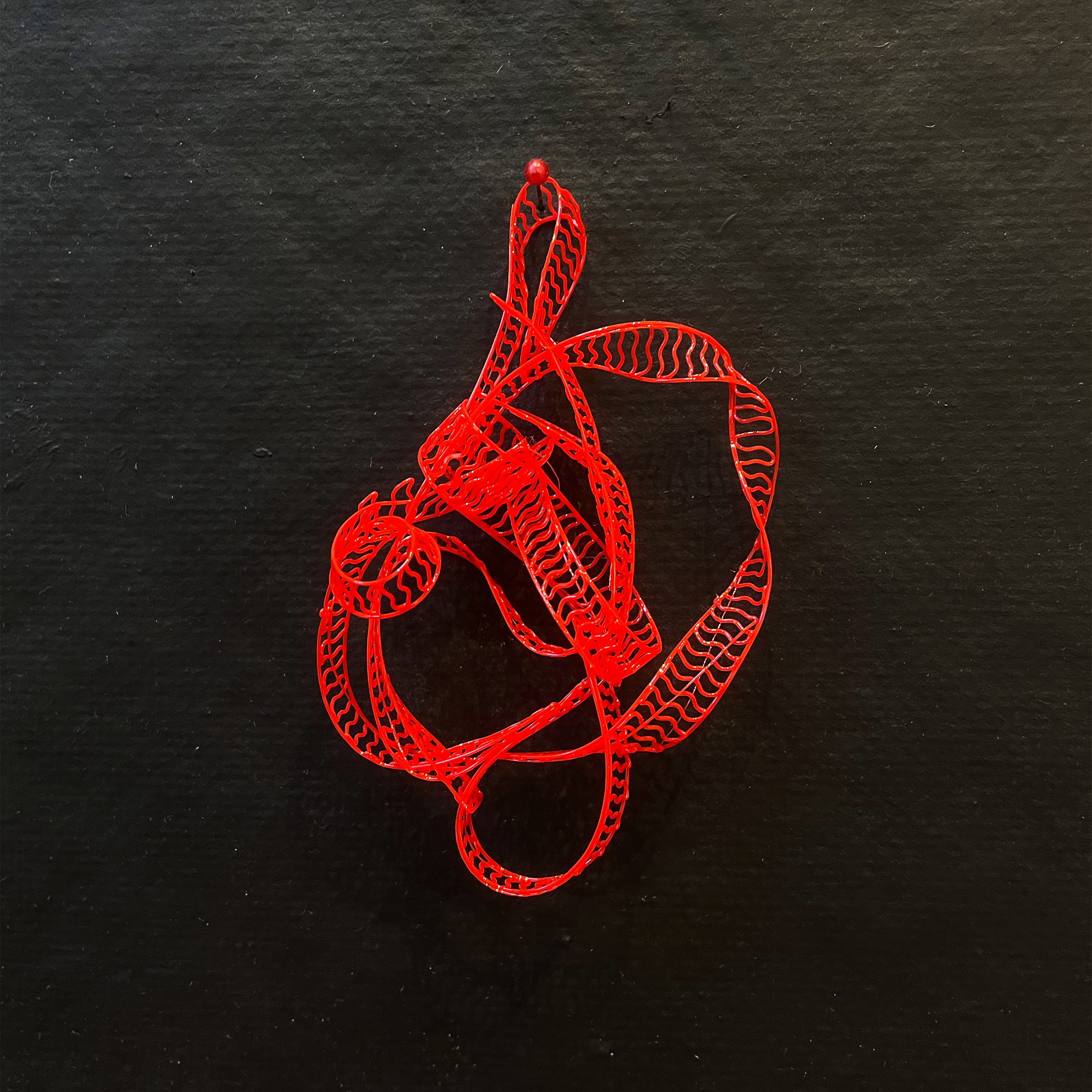

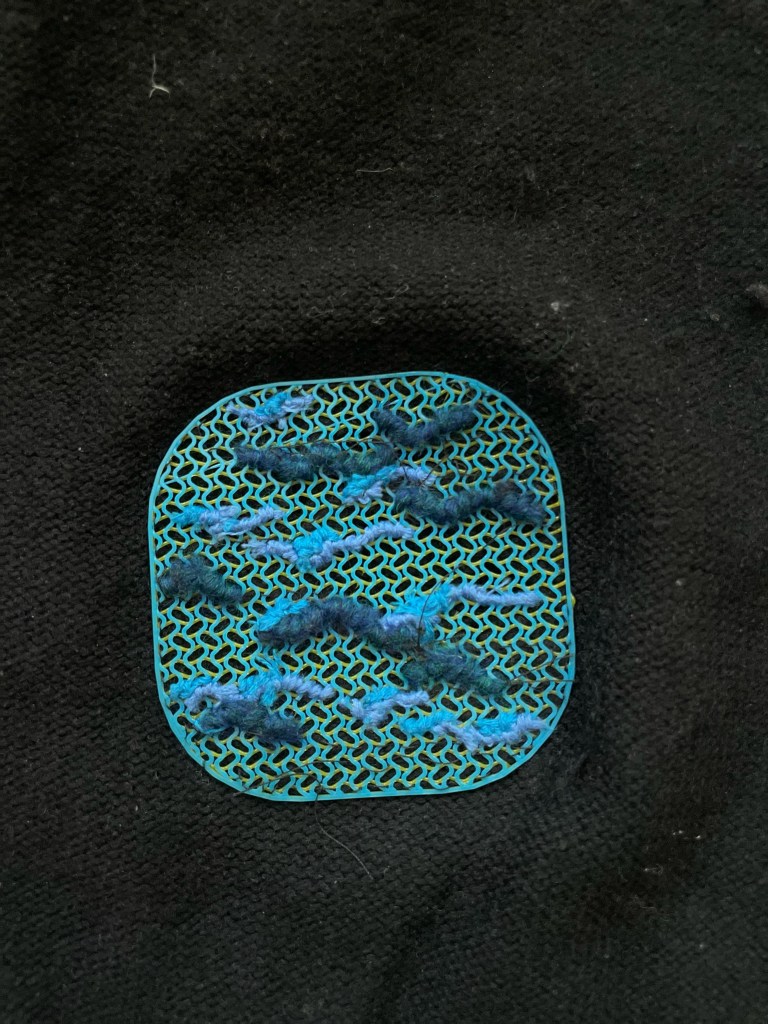

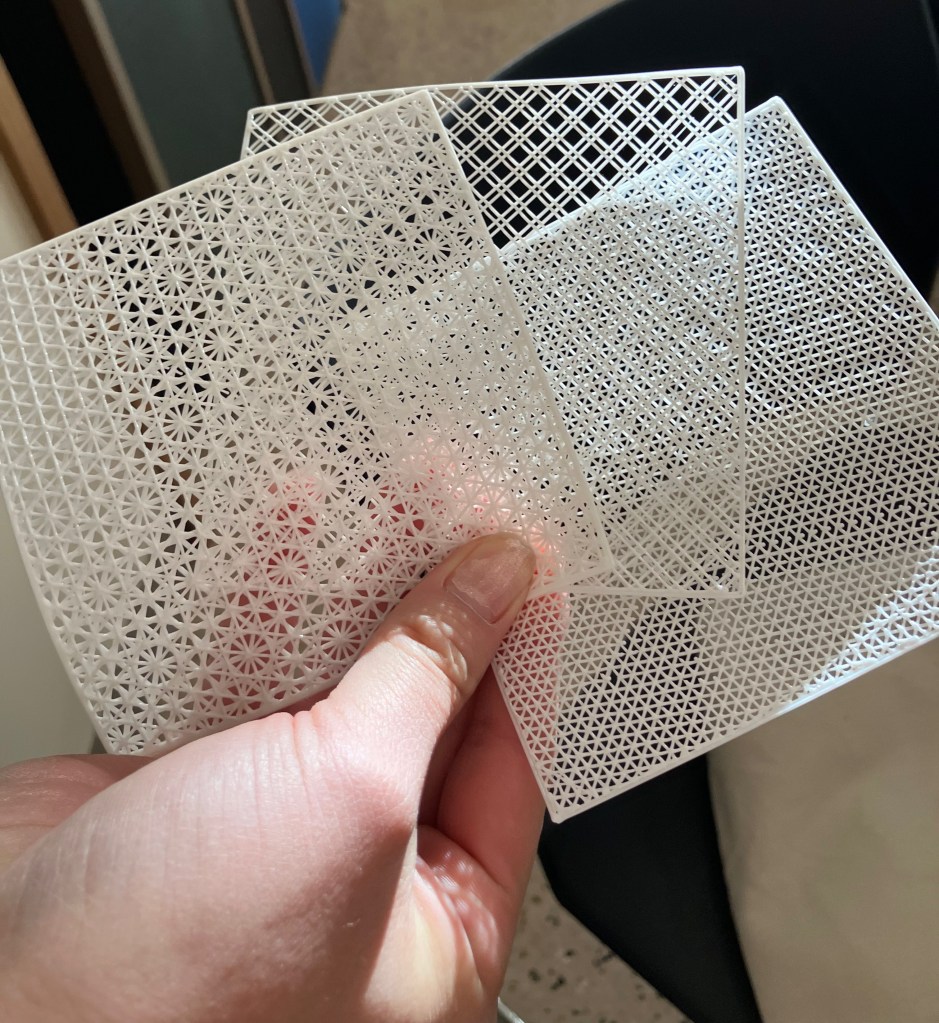

From here I was able to widen the possibilities of patterns and therefore material properties as I better understood my work flow and the abilities of my tools.

Where on the body would I need the most stretch? In what ways? Some of these geometries would be perfect for an elbow! In what ‘wear patterns’ should the textile be thicker/thinner? How airy can my patch be before it’s not durable? How best can I strike a balance between a hardy textile and an aesthetic adornment?

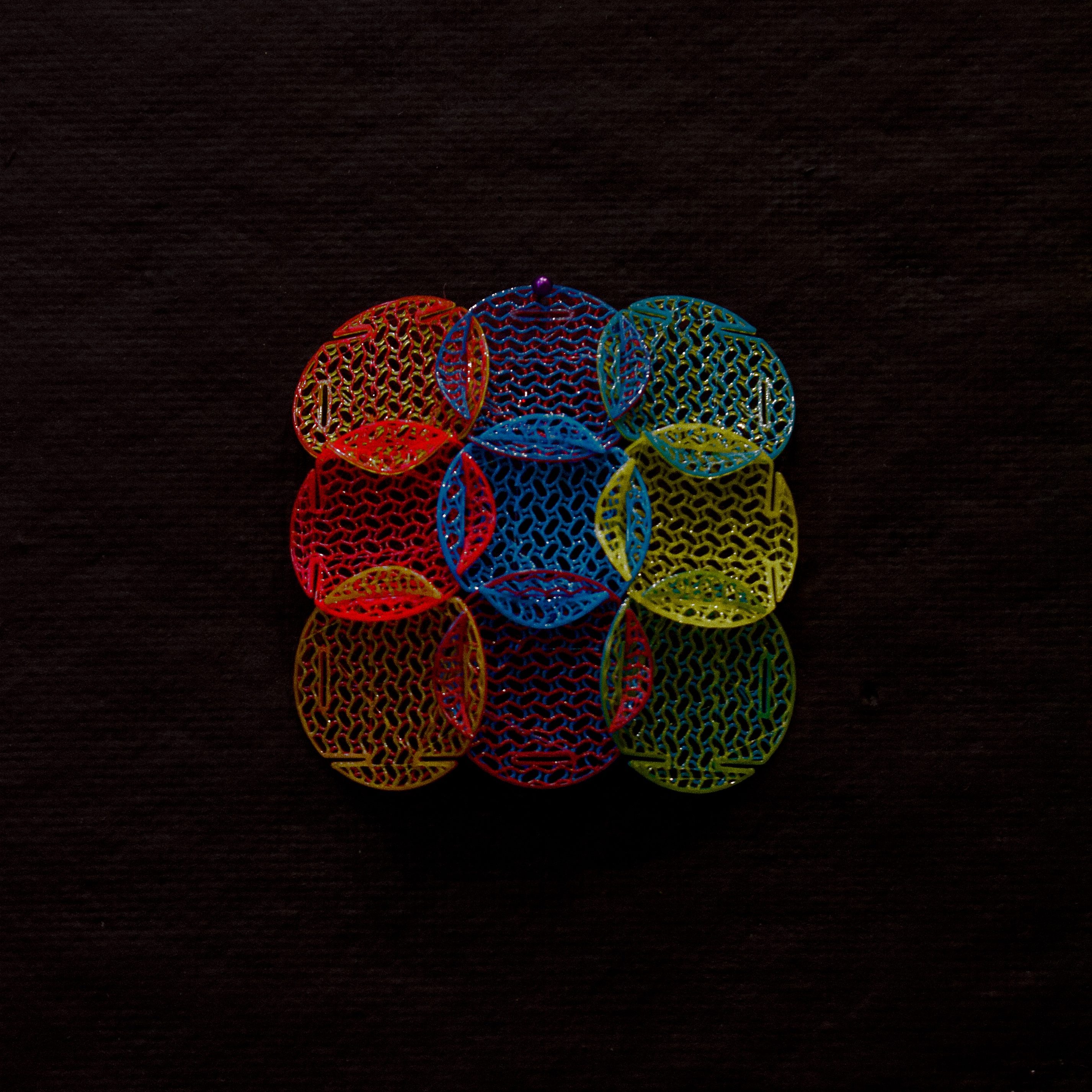

I then combined this research with my original hand embroidered patches to create new versions of the sweaters with TPU patches for each person. Along the way I started pushing the limits of the 3D printer’s capacity. Our printers in the Digital Design Studio at Wes only had one nozzle, so prints could only ever be one color. As well, the TPU manufacturer only created five colors; Red, blue, yellow, black, and white. I learned to manually override this system, creating multicolor prints and therefore expanding the three primary colors available to all possible permutations (red & yellow, yellow & red, red & blue, blue & red, etc.)

My TPU Sweater

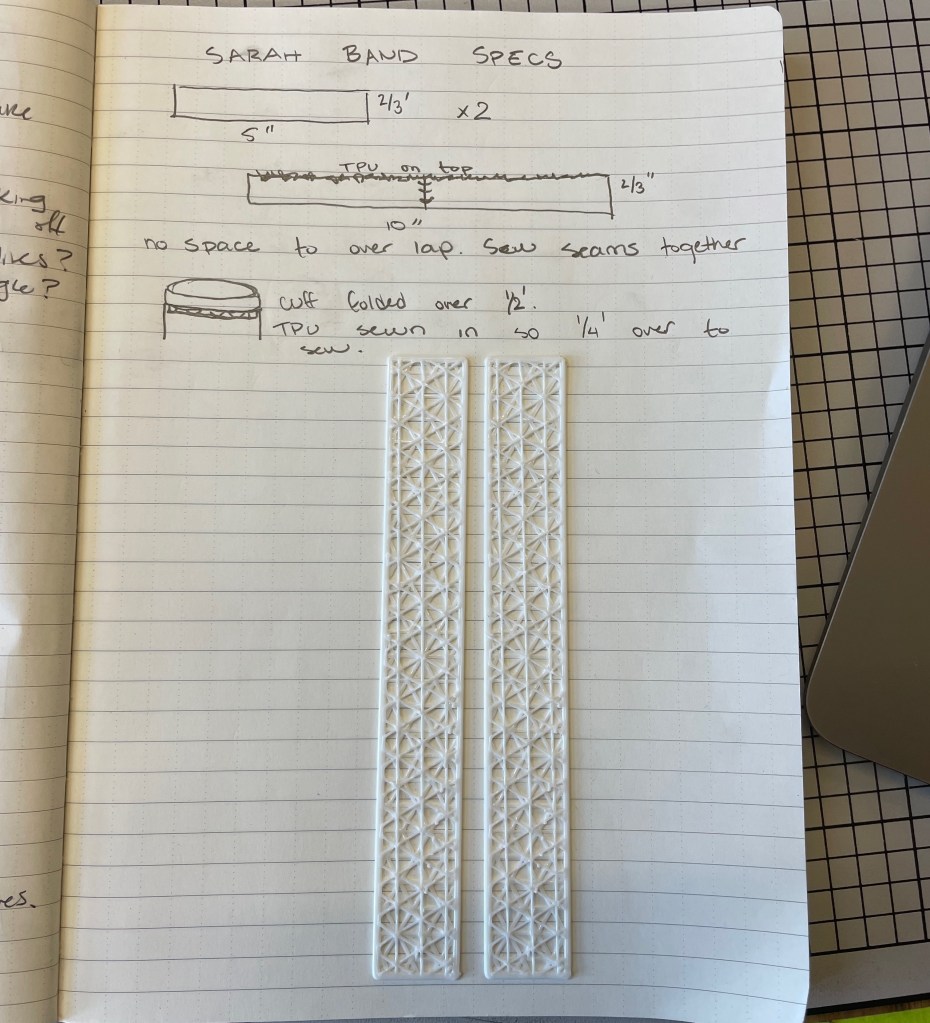

Sarah’s first TPU sweater

Sarah’s second TPU sweater

This ‘patch’ was visible from the onset of creation as Sarah was too excited to wait for the eventual wear down and reveal

Emma’s TPU sweater

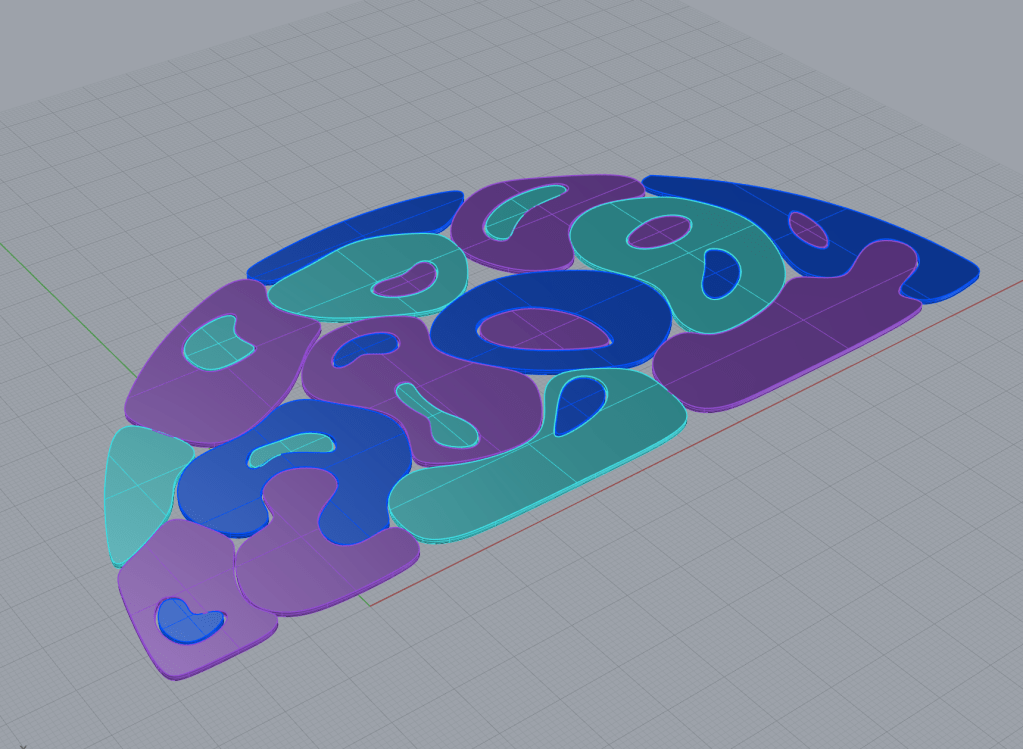

Emma’s two hip patches ended up being comprised of 26 pieces each. I really wanted to apply all that I had learn to these last patches and so added in some of the permeations of colors: red & blue, blue & yellow, blue & blue. As well, in line with Emma’s inspo board we brought in the organic amorphous shapes she liked.

In total there were 26 of these files

Once these patches were done, I kept experimenting throughout the rest of my thesis. I saw this work as an extension of the thesis, exploring structure, form and the body, connection, constraints, and a lot of ‘what if?’s. By the time my thesis came around I had produced 48 of these ‘squares’ that I mounted on black boards. Here are 20 of the 48 that were shown in the gallery.

20 of 48 Squares