Biological Swimmer

Project Overview

Create a biological swimmer to navigate through a pool

Duration

1 month

Team Project

My job: electronics, waterproofing

Introduction

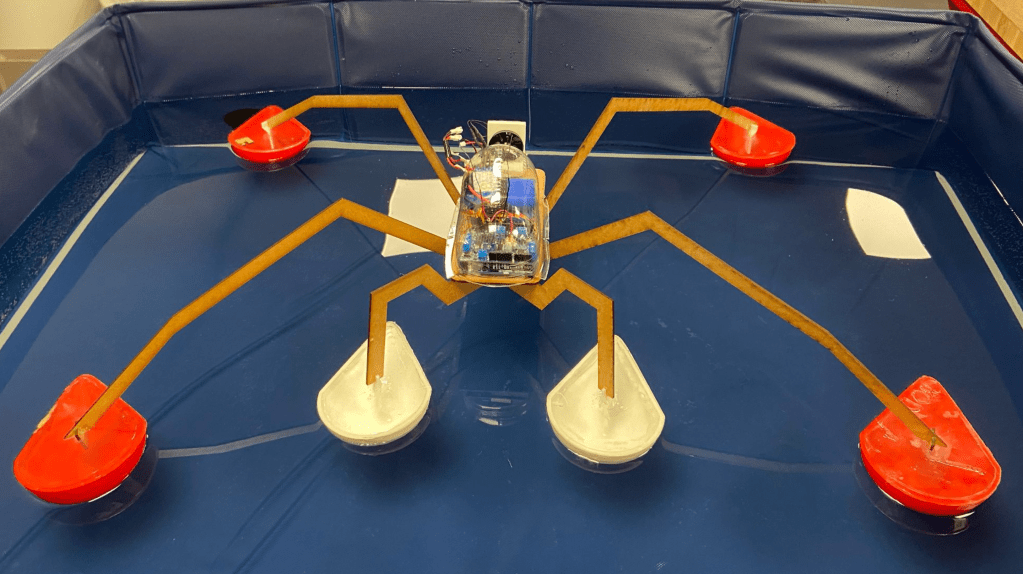

We chose the Water Skeeter which strides above the water through use of surface tension and long legs that have hydrophobic properties to model our swimmer after.

Preliminary Thoughts and Questions

We knew that we would need large hollow feet that could float above the water, however we didn’t know how large as it depended on the weight of the bug which we had yet to know. We went ahead with an educated guess for the first rendition.

We also knew we needed to have something to propel the bug across the water, probably a fan. How would we control this fan? How would we power it while the bug is was moving? How do we make sure the bug stays dry, especially if we had electronics on board?

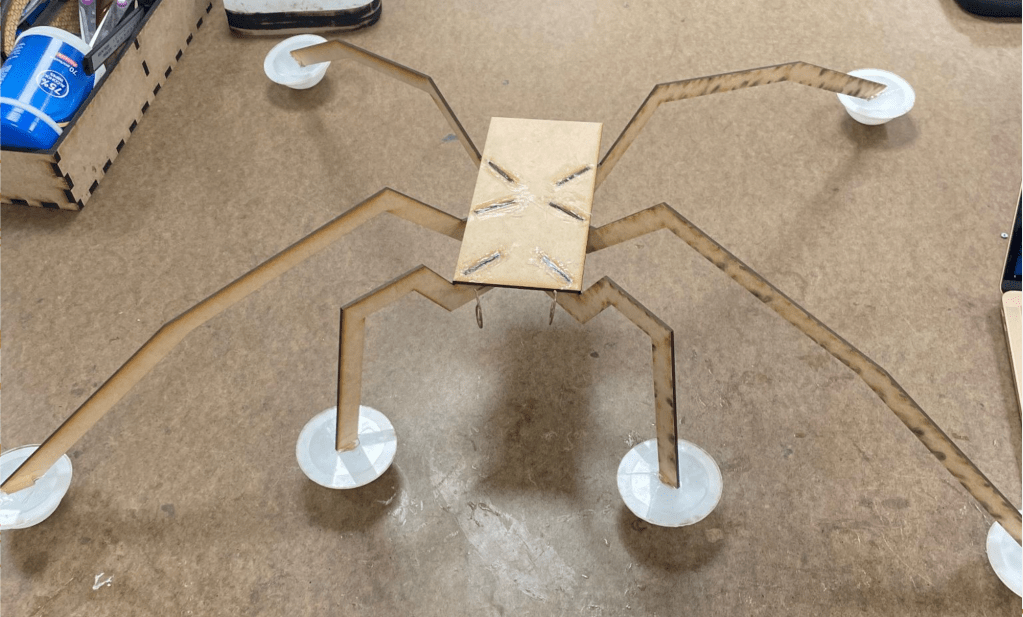

First Prototype – Body

After printing our first feet, we soon realized that we would need bigger versions to displace more weight as the bug barley carried its own mass let alone electronics. We also noticed that because we were staying as close to the ratio of a real water bug as possible, we had minimal space for the rest of the components that would sit on the back of the bug.

Second Prototype – Body

While creating bigger feet we also rethought the shape to be more fluid dynamic. As most things go, while we recognized and addressed a number of large issues with our feet, a small detail slipped our minds. We cut the holes in the plexiglass the wrong way! We fixed this by printing MDF pieces that could insert into the plexiglass vertically and the end of the bug’s leg horizontally, putting the feet back in the correct position.

Electronics (My main job)

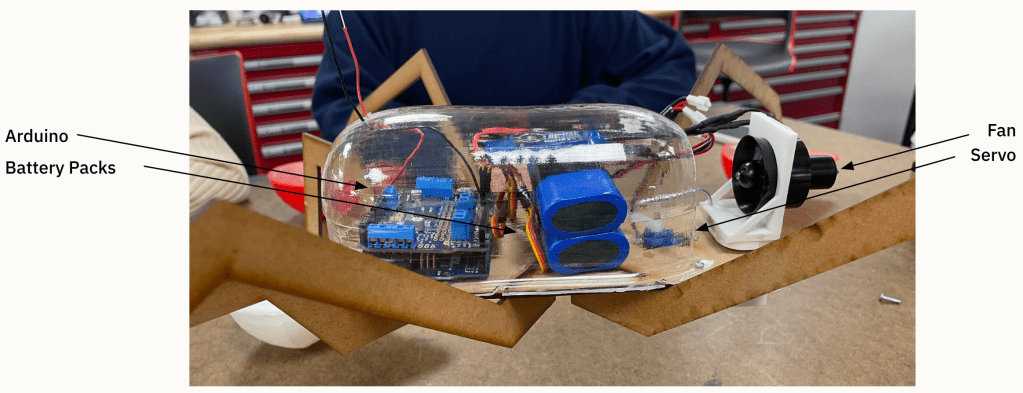

The electronics took a lot of planning. They needed to be waterproofed, self contained on the back of the bug through use of battery packs and light enough to not sink the bug but still have enough power for the arduino, fan and servo.

Work on the code for the arduino/RC fan went exceedingly slowly at first as none of us had worked with such technology and we soon realized we needed help. We reached out to and met with an electronics professor and got lost in hours of RC fan forums, finally realizing we needed a translator between the arduino and fan.

We also had to tackle the problem of steering the bug which we decided to do with a servo. After a lot of trial and error in Solidworks, we mounted the fan on a 3D printed swivel and connected it to the servo with a small metal pipe so that its direction could be changed with the servo through use of the arduino.

Waterproofing (My side job)

In order to create a protective shell but satisfy the need of a light weight solution and the desire to still have our electronics visible, we decided to try vacuum forming. We created a half bean shape using laser cut MDF and a round 3D printed top piece and then created a shell of the bean with the vacuum former.

Wrapping Up + Teamwork Reflections

We joined all of the pieces we had been working on separately, including the electronics, feet, body and shell, to complete our bug.

This project really stressed the importance and some times difficulty of team work. While we each were challenged to learn new hard skills, it was the soft skills of communication, organization and patients that I found most valuable. We needed to make sure we were constantly all on the same page and working towards an intertwined goal so that our individual pieces could fit seamlessly together in the end. When differing opinions arose, which happened often at the beginning of our project, we would discuss them as a team and make time for each teammate to have their opinion heard. By making sure to have our voices heard, we avoided any silent feelings of disdain which we realized bread fast and are sometimes hard to pick up on by others.